1. Overview

XHT-5 visible light flame detection device is a new generation flame detection device of our company, which is suitable for detecting the combustion of various fuels, displaying the flame intensity and pulse frequency inside the furnace, and realizing fault self inspection, indication, and signal output. It consists of a flame detection probe and a signal processor. It uses digital processing technology and new pattern recognition software and hardware to quantify the target flame, improving the accuracy of detection. It is widely used for flame detection of various fuels and coal in power stations, metallurgy, petrochemical, and other fields.

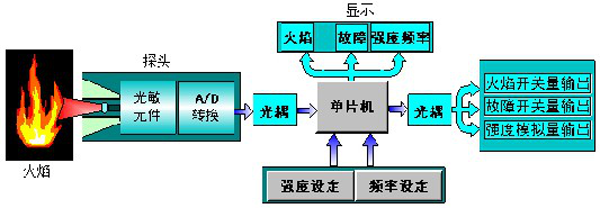

2. Working principle

The target flame is focused by the lens group and transmitted to the preprocessing circuit board through optical fibers. After converting the visible light signal into electrical signals, the intensity and pulse frequency of the flame are digitally processed, and finally transmitted to the processor. The CPU in the processor collects the signals transmitted from the probe, processes and calculates them, and displays the intensity and pulse frequency of the flame on the digital tube. At the same time, the intensity of the flame is displayed in the form of a light column, and automatically identifies it according to the preset fire and no fire identification standards. Finally, the corresponding signals and instructions are given.

3. Main technical parameters

sensitivity | ≥100Lx ( λ 0= 920nm) | ||

response time | catch fire | ≤1s | |

Flameout | ≤3s(adjustable) | ||

Detection object | Fuel oil, coal flame | ||

Signal output | Method | Two sets of normally open/normally closed contacts | |

Capacity | AC220V 50Hz 2A ,DC24V 2A | ||

Analog output | 4~20 mA ,1~5V DC | ||

operation mode | Long term continuous work | ||

orking environment requirements | probe | ≤80℃(Air cooled) | |

Signal processing box | ≤50℃ | ||

ambient humidity | ≤85%RH | ||

Cooling method | Air cooling: probe cooling air volume ≥ 60 m3/h, air temperature ≤ 50 ℃, probe cooling air inlet and furnace pressure difference ≥ 2000 pa | ||

Power supply | AC220V 50Hz | ||

power dissipation | 10 W | ||

Detection distance | 400~6000mm | ||

4. Model Selection

(1) Flame detection probe

The flame detection probe mainly consists of an optical lens set, optical fibers, and a preprocessing circuit board. Optical fiber has excellent light transmittance, which transmits the signal of the target flame from one end of the lens set to one end of the preprocessing circuit board with extremely low attenuation.

There are two types of flame detection probes: endoscope type and endoscope type. The endoscope probe is placed inside the furnace near the flame spout, which is convenient to avoid interference from other light sources during operation and has accurate output signals; The external probe is installed outside the furnace wall, with a relatively long distance from the detected target flame and relatively low detection accuracy.

Endoscopic probe rod structures are divided into two types: soft rod swing and hard rod non swing. When a boiler uses a swing burner, the flame detector should be equipped with a soft rod swing structure, so that it can swing synchronously with the burner nozzle and track the flame for accurate judgment.

(2) Flame detection processor

The flame detection processor has two structural forms: instrument type and plug-in box type, and the forms are as follows:

5. Product Legend

Tel: 0516-81915686 Fax: 0516-81915687

Website: www.jinengdianli.com Email: xzjndl@163.com

Headquarters address: No. 6, Software Park Road, Quanshan District, Xuzhou City, Jiangsu Province

Manufacturing base: No. 2, Fumin Road, High tech Industrial Development Zone, Xuzhou City, Jiangsu Province